|

| |

Phase-Change Media for CSP Thermal Energy Storage

We conduct our discussion of the potential difficulties that

accompany the use of PCMs as thermal storage media with a list of the basic

requirements that any potential PCM storage media must meet, as suggested by

Kenisarin (Kenisarin 2010):

-

Appropriate melting

temperature. The temperature must be within the operating range of

interest--usually comfortably within that range, so as to provide a buffer

for any transient effects (e.g., supercooling). Often times, appropriate

temperatures can be obtained by eutectic combinations of other salts, either

binary of ternary.

-

High specific heat, enthalpy of

fusion, and density. In other words, the PCM should have a high thermal

storage capacity, as would be expected of any successful candidate TES

medium.

-

Congruent phase change.

Congruent phase change, as opposed to incongruent phase change, results in

equal compositions of PCM constituents in both (solid and liquid) phases.

Contrast this with incongruent phase change, in which separate phases of

varied composition will appear at solidification--such is the case with

eutectics, although if their macrostructure remains relatively uniform

(e.g., lamellar microstructure), the effects of heterogeneity may be

negligible. Also, metal alloys may display incongruent melting, depending on

their composition.

-

Reliable convertibility after

repeated cycling. As may be the case with incongruent phase change, or if

phase change occurs in the presents of labile impurities, repeated thermal

cycling may compromise the thermophysical properties of the PCM. It has been

demonstrated that both the enthalpy of fusion and the melting temperature of

various eutectic salts and metal alloys can decline markedly after thermal

cycling on the order of 1000 times (Kenisarin 2010). Single-component salt

PCMs seem less prone to this problem.

-

High thermal conductivity. The

thermal conductivity will dictate the transient behavior of the storage

system, although convective effects will play a major role, as well

(Hernandez-Guerrero, Aceves et al. 1999). Unfortunately, most salts

considered in the context of PCMs display relatively low thermal

conductivities, on the order of 1 W/m-K (Kenisarin 2010). Use of adjuncts or

additives that improve the conductivity of these materials has been

investigated--specifically, graphite-salt composites show much improved

conductivity, while generally retaining desired phase change characteristics

(Pincemin, Olives et al. 2008). Container ribbing or incorporation of fins

are other possible means of improving heat transfer in poorly conductive

PCMs (Fernandes 2012). On the other hand, metal alloys may be a useful

substitute as high conductivity PCMs, thought they have their own

complications.

-

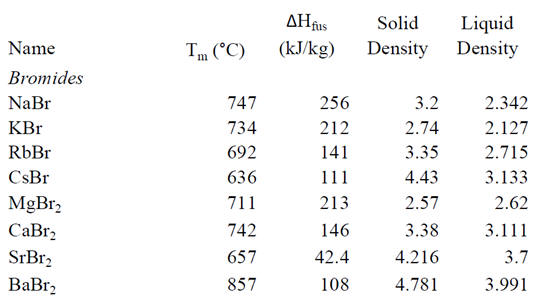

Tolerable volume change upon

phase change. Salts tend to have significant volume changes upon phase

change, and it is up to the designer to choose among candidate PCMs

appropriately and account for this effect. For illustration, we include a

table of bromide salts with the melting points and density changes upon

melting (Lide and Frederikse 1995). As can be seen, among these salts,

magnesium bromide appears the best suited for applications in which the

volume can change relatively little. Also, metal alloys typically have the

advantage of low volume change upon melting.

-

Insignificant supercooling.

Supercooling is the phenomenon whereby a system can cool to below its phase

change temperature without undergoing a phase change, usually the result of

a metastable state forming due to lack of nucleation points (Sandler 2006).

Such behavior is characteristic of crystalline salts, and can lead to rather

drastic transient effects (Kenisarin 2010). Here, again, metal alloys tend

to avoid this issue.

-

Chemical stability. The PCM

must remain chemically inert over the life of its use--ideally on the order

of many years.

-

Compatibility with construction

/ container / encapsulation materials. Material compatibility can be a

problem with salts especially, many of which have a high tendency to corrode

common construction materials such as iron. As such, extensive research has

been conducted investigating potential encapsulation techniques for use with

these PCMs (Zalba, Marin et al. 2003). Of course, metal alloys typically

will not cause corrosion, and so may be a worthwhile choice in this regard.

-

Tolerable toxicity. The

toxicity of these compounds warrants attention--the inclusion of adequate

health and safety measures in the manufacturing design may introduce

unforeseen costs.

-

Flame and fire safety. Again,

additional health and safety measures to contain the threat posed by

flammable or explosive candidate PCMs will likely introduce unforeseen

costs. Thus, these materials should be avoided.

-

Cost. Since the main point in

investigating PCMs is to reduce cost through improved efficiencies and

greater storage capacities, it is counter intuitive to select a

prohibitively expensive PCM, no matter how attractive its thermal transfer

properties may be. Hence, it is unlikely that materials incorporating rare

elements will find successful use in PCM storage systems. This criterion

also limits the applicability of many metal alloys.

Other issues related to the handling of PCM materials will

need to be addressed prior to manufacturing scale-up. For instance, the

hygroscopicity of many of the salts considered here will require rigorous care

to avoid infiltration of moisture into the encapsulated PCM matrix; in many

cases, the presence of moisture can drastically alter the phase change

temperature and overall chemical stability of the salt.

|